制造业最重要的概念是精密度。它有两个概念,一个是加工精度,另一个是测量精度。

The most important concept of manufacturing is precision. There are two concepts in it, one is machining accuracy and the other is measuring accuracy.

How to reflect the size that the designer is hoping for is the machining accuracy, and how to know the size of the machining is the measurement accuracy. Both of these precisions are directly dependent on the accuracy of the machining machine or the working machine of the measuring machine. The machining accuracy of mechanical equipment will only be lost without increasing. The 1/100 mm precision machine can only process workpieces with an error of 1/100 mm or more, so even if the assembly error is not considered, the medium machining accuracy is used. Machines assembled with machined parts can only reach lower precision. To consume parts assembled into medium-precision machines, only high-precision machining machines can be used.

如何反映设计师希望的尺寸是加工精度,如何知道加工尺寸是测量精度。这两种精度都直接取决于加工机或测量机的加工机的精度。机械设备的加工精度只会在不增加的情况下损失。1/100毫米精密机床只能加工误差在1/100毫米或以上的工件,因此即使不考虑装配误差,也采用中等加工精度。用机械零件装配的机器只能达到较低的精度。要消耗组装成中精密机床的零件,只能使用高精密机床。

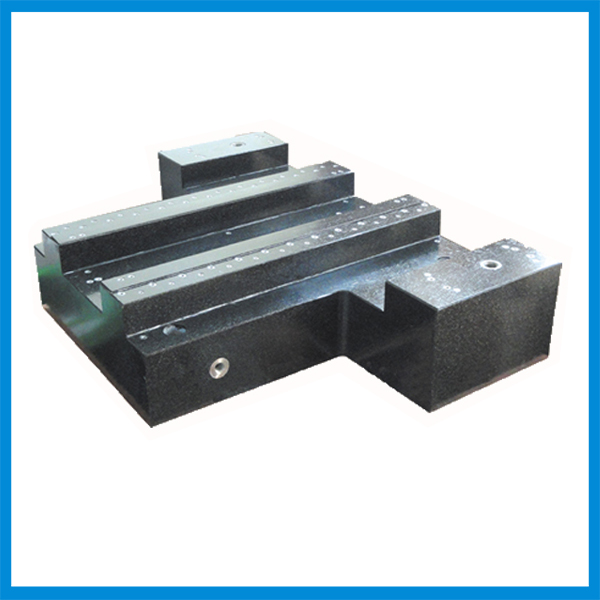

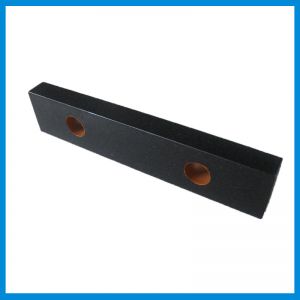

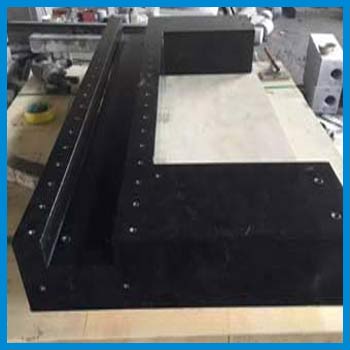

According to this principle, to manufacture high-precision machining machines, only ultra-high-precision machining machines can be used. This raises a question: how the so-called "ultra-precision machining machinery" is manufactured and manufactured. The answer may be unpredictable. "Ultra-precision machining machines" are made by hand. When it comes to "precision", it is reminiscent of the technical terms of "computer" and "digital". In theory, precision has nothing to do with those fashionable terms. Before those fashionable terms were presented, humans could have reached high precision. It is. The most important influence on the precision of the machining machine is the rail portion. The moving part of the machine is limited by the guide rail, and the accuracy of the guide rail directly determines the accuracy of the mechanical movement. The sliding surface of the ultra-precision mechanical guide is called "absolute plane" and requires an accuracy of 1/10000 mm or more. Now there is no mechanical machine capable of processing such an absolute plane, which can only be processed by hand.

___根据这一原理,制造高精度加工机械,只能使用超高精度加工机械。这就提出了一个问题:所谓的“超精密加工机械”是如何制造和制造的。答案可能是不可预测的。”超精密加工机”是手工制造的。说到“精确性”,它让人联想到“计算机”和“数字”的技术术语。理论上,精确性与那些时髦的术语毫无关系。在这些时髦的术语出现之前,人类本可以达到高精度。它是。对机床精度影响最大的是导轨部分。机床的运动部分受导轨的限制,导轨的精度直接决定机械运动的精度。超精密机械导轨的滑动面称为“绝对平面”,要求精度为1/10000mm或更高。现在没有一台机械能处理这样一个绝对平面,只能用手工处理。

Anyone who has seen the sliding surface of a high-precision machine tool guide knows that the so-called "absolute plane" is not a smooth mirror, but a plane that has a regular pattern, and those patterns are the blades of the craftsman who made this plane. Traces underneath.

在下面留下痕迹。

The absolute plane manufacturing process is like this: Xu Zhenjia, a craftsman with experience, uses a blade to level the plane obtained by roughing, and while he is scooping out the plane of the demand, he still makes a contrast plane, and then on the control plane. Apply the color and slide the processing plane on the control plane. At this time, the color part on the processing plane and the color part on the control plane are the higher parts on the two planes, and the demand is shoveled again. The process is repeated abruptly, from time to time the color of the two planes is up to the uniform, and the knife marks left on the plane are just as the lubricating oil groove, double-edged. But this is not an absolute plane, because it is assumed that the same curvature between the two faces will produce the same effect. This is just that the two faces are intact and cannot be guaranteed to be flat, so another reference plane is required. . Generally speaking, when machining an absolute plane, it is necessary to process three planes at the same time. In the three planes, the two sides are divergent, and the absolute plane is calculated.

绝对平面制造工艺是应用颜色并在控制平面上滑动处理平面。此时,加工平面上的颜色部分和控制平面上的颜色部分是两个平面上的较高部分,需求再次被铲平。这一过程是突然重复的,不时的两个平面的颜色达到均匀,平面上留下的刀痕就像润滑油槽一样,是双刃的。但这不是一个绝对平面,因为假设两个面之间的相同曲率会产生相同的效果。这只是两个面是完整的,不能保证是平的,所以需要另一个基准面。一般来说,加工一个绝对平面时,需要同时加工三个平面。在三个平面中,两边是发散的,并计算出绝对平面。

The companies that normally use the absolute planes required for this type of process machinery are mainly in Germany, Switzerland and Japan, which is why these countries can consume high-precision mechanical equipment. This kind of precision processing company in Japan is mainly concentrated in the area around the 43 degree north latitude of Niigata Prefecture. There is a climatological reason here. The Japanese craftsmanship was learned from the Germans. At that time, when the government selected the address of the precision processing industry, the climate was selected to be similar to the 43 degree north latitude in Germany. The humidity is small and the temperature is also coiled at around 20 degrees Celsius, which is most suitable for precision machining. At that time, there was no air-conditioning equipment. It is unimaginable to install air-conditioning equipment in the consumer workshop. Therefore, it is necessary to pay attention to the temperature difference when selecting the site. The material expansion and contraction caused by the temperature difference has a great influence on the manufacture and assembly of precision products.

通常使用这种加工机械所需的绝对平面的公司主要在德国、瑞士和日本,这也是这些国家能够消费高精度机械设备的原因。日本这种精密加工公司主要集中在新泻州北纬43度左右的地区。这里有一个气候原因。日本的工艺是从德国人那里学来的。当时,政府在选择精密加工工业的地址时,选择了与德国北纬43度相似的气候。湿度小,温度也在20摄氏度左右,最适合精密加工。当时没有空调设备。在消费品车间安装空调设备是不可想象的。因此,在选址时应注意温差。温差引起的材料膨胀和收缩对精密产品的制造和装配有很大的影响。

The temperature difference not only affects the workpiece, but the bed of the ultra-precision grinder that I have seen does not use ordinary cast iron, but uses granite to reduce the influence of temperature difference. These enterprises are basically small companies with several people to dozens of people. It is said that small workshops are not too hot, but apart from these small workshops, world-renowned mechanical brands such as Yasuda, Mori and Makino cannot be established. The Japanese economy has been sluggish for more than a decade, but these companies that are engaged in the manufacture of sliding planes have never been affected. Because this industry is the most fundamental of manufacturing, demanding technology and rich experience, it has only been Not enough, no excess. In particular, as the range of applications of electronic technology expands from time to time, the demand for high-precision processing machinery will only increase from time to time without reducing.

这些企业基本上都是小公司,有几人到几十人。据说,小作坊并不太热,但除了这些小作坊之外,还无法建立起世界知名的机械品牌,如Yasuda、Mori和Makino。日本经济已经停滞了十多年,但这些从事滑动飞机制造的公司从未受到影响。因为这个行业是制造业最基础、技术最苛刻、经验最丰富的行业,所以它只是不够,没有过剩。特别是,随着电子技术应用范围的不断扩大,对高精度加工机械的需求也只会不断增加而不会减少。

0755-2330 1799 手机 136 3284 0096

0755-2330 1799 手机 136 3284 0096